Plastic Welding

We use the most modern and up-to-date techniques to carry out plastic trim & bumper repair. We have specialist plastic welding equipment and specific bonds & resins to match the plastic type. Making a cost-effective repair to reduce the costs of replacing whole panels, bumpers, trims & mirrors.

If you have a cracked bumper or any cracked plastic trim we can repair it!

Should I make an insurance claim?

If your bumper has minor damage, the repair costs may be lower than your insurance excess. In this instance, you may choose not to claim and pay for a minor repair to fix the damage, which will also help you avoid increased insurance rates in the future. Often, some bodyshops will replace rather than repair as they earn more money from the insurance company

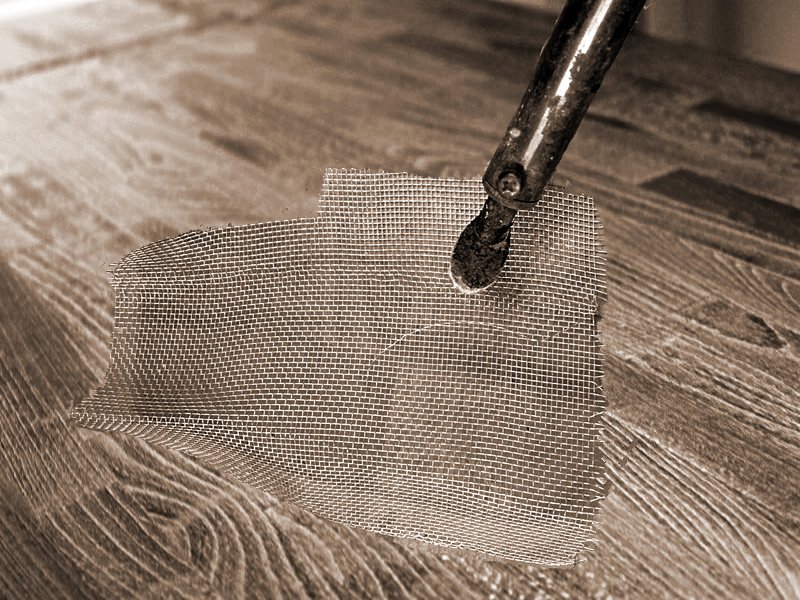

Speed Tip Welding

This process involves a tool similar to an electric soldering iron in appearance and power output. However, it is fitted with a feed tube for the plastic weld rod. The tip of the iron heats the plastic rod and the substrate, while at the same time, it presses the molten weld rod into position. A strip of softened plastic is laid into the joint fusing the plastic weld and the two parts together. When using polypropylene, the melted welding rod must be mixed with the semi-melted base material that is being repaired. Not all vehicle manufacturers use the same type of plastic. We have access to information to know which base plastics are used, thus getting the right plastic for welding. Speed tip welding is a fast & effective technique and can be used in tight corners which makes it ideal for trim & bumper repair